Supply (197)

How to Utilize Digital Twins in Supply Chain Management

Digital twins have emerged as an effective strategy for overcoming disruptions and building resilience in supply chains. They can deliver data-driven insights and integrated planning capabilities that improve operations and keep business flowing smoothly.

Here’s how digital twins can improve supply chain management and how managers can implement them.

Read more...Cannabis Supply Chain Challenges in the USA: Navigating Complexities in a Rapidly Growing Industry

- Monday, 11 December 2023

- Supply

- Written by Scott Koegler

As more states in the USA legalize the recreational use of cannabis, the cannabis industry has grown in a rapid pace never anticipated by anyone. With this growth, however, comes various unique challenges for the cannabis supply chain. From cultivation to distribution and sales, each stage of the supply chain presents its own set of complexities that need to be overcome. This article sheds light on the intricacies of the cannabis supply chain and explores the obstacles faced by growers, distributors, and retailers within the industry. Examining regulatory compliance, quality control, transportation logistics, and marketing strategies the article article will provide a thorough understanding of the unique issues the cannabis industry faces in the ever-evolving landscape of legalization.

Read more...Optimizing Supplier Relationship Management with E-Procurement Systems

- Monday, 16 October 2023

- Supply

- Written by Scott Koegler

The business landscape has become unbelievably competitive in the world today, regardless of the industry. With this increasing competition, establishing strong supplier relationships is crucial for organizations to achieve their strategic goals. Although there are various ways of establishing a strong supplier relationship, one of the best and most effective tools that can streamline this process is the use of e-procurement systems. These software solutions offer a range of features that enable businesses to maximize the benefits of their supplier relationships and drive operational efficiency.

Read more...Supply Chain Simulation Models for Risk Analysis

- Monday, 09 October 2023

- Supply

- Written by Scott Koegler

Supply chain simulation models have become essential tools for supply chain managers. These tools allow supply chain professionals to analyze and optimize their operations with more ease and freedom than ever. Thanks to these models, supply chain industry players now have access to dynamic details and insights which has allowed them to expand the design analysis and optimization capabilities for supply chain managers. Through the combination of analytical optimization and dynamic simulation methods, supply chain managers can effectively address complex supply chain problems and lay the foundation for advanced supply chain development.

Read more...The Importance of Supply Chain Resilience

- Monday, 17 July 2023

- Supply

- Written by Scott Koegler

Supply chain disruptions can have a significant impact on businesses, affecting their operations, finances, and reputation. Therefore, it is essential for companies to prioritize supply chain resilience and develop strategies to prepare for potential disruptions. Supply chain resilience refers to an organization's ability to quickly recover and adapt to unexpected disruptions while maintaining its operations and minimizing the impact on its stakeholders. Here are some reasons why supply chain resilience is crucial:

Read more...Supply Chain Risk Mitigation Strategies

- Monday, 10 July 2023

- Supply

- Written by Scott Koegler

With the unpredictable world that we live in today, having solid risk mitigation and contingency planning strategy is necessary to maintain uninterrupted operations and build resilience in supply chain logistics. With data-backed insights and proactive measures, businesses can navigate uncertainties and ensure a smooth flow of goods and services. In this blog post, we delve into supply chain and try to understand effective strategies to safeguard it against potential disruptions and enhance overall operational resilience.

Read more...Despite Challenges, Microfulfillment Warehouses are Transforming E-commerce

- Monday, 03 July 2023

- Supply

- Written by Camille Manso

Order fulfillment – the process of preparing and delivering a customer’s order, including warehousing, packing, labeling, and shipping – is core to an effective supply chain. But the way companies fulfill orders is changing, and that creates new risks and opportunities for retailers, logistics providers, and other ecosystem stakeholders. In the wake of these changes, consumers' expectations have also increased: they demand faster delivery, lower costs, and greater accuracy. To meet these expectations, retailers are getting savvy with how they use physical space, and both retailers and logistics providers are experimenting with new warehousing and fulfillment models. Among those in use are ship-from-store and dark stores, but neither are necessarily within close proximity of the customer. And that is another challenge.

Read more...Impacts of Supply Chain Challenges

- Friday, 23 June 2023

- Supply

- Written by Scott Koegler

The year 2020 brought unprecedented challenges for businesses worldwide, and the manufacturing industry was no exception. The COVID-19 pandemic disrupted global supply chains, causing widespread shortages of raw materials and finished goods. Additionally, natural disasters, trade disputes, and political tensions added to the complexity of supply chain management. As a result, manufacturers had to quickly adapt their processes to overcome these challenges and continue delivering products to the market. In this blog post, we will take a closer look at the recent supply chain challenges faced by manufacturers, their impact on the industry, and potential solutions for overcoming them.

Read more...The Benefits of Automated Supply Chain Management

- Monday, 29 May 2023

- Supply

- Written by Scott Koegler

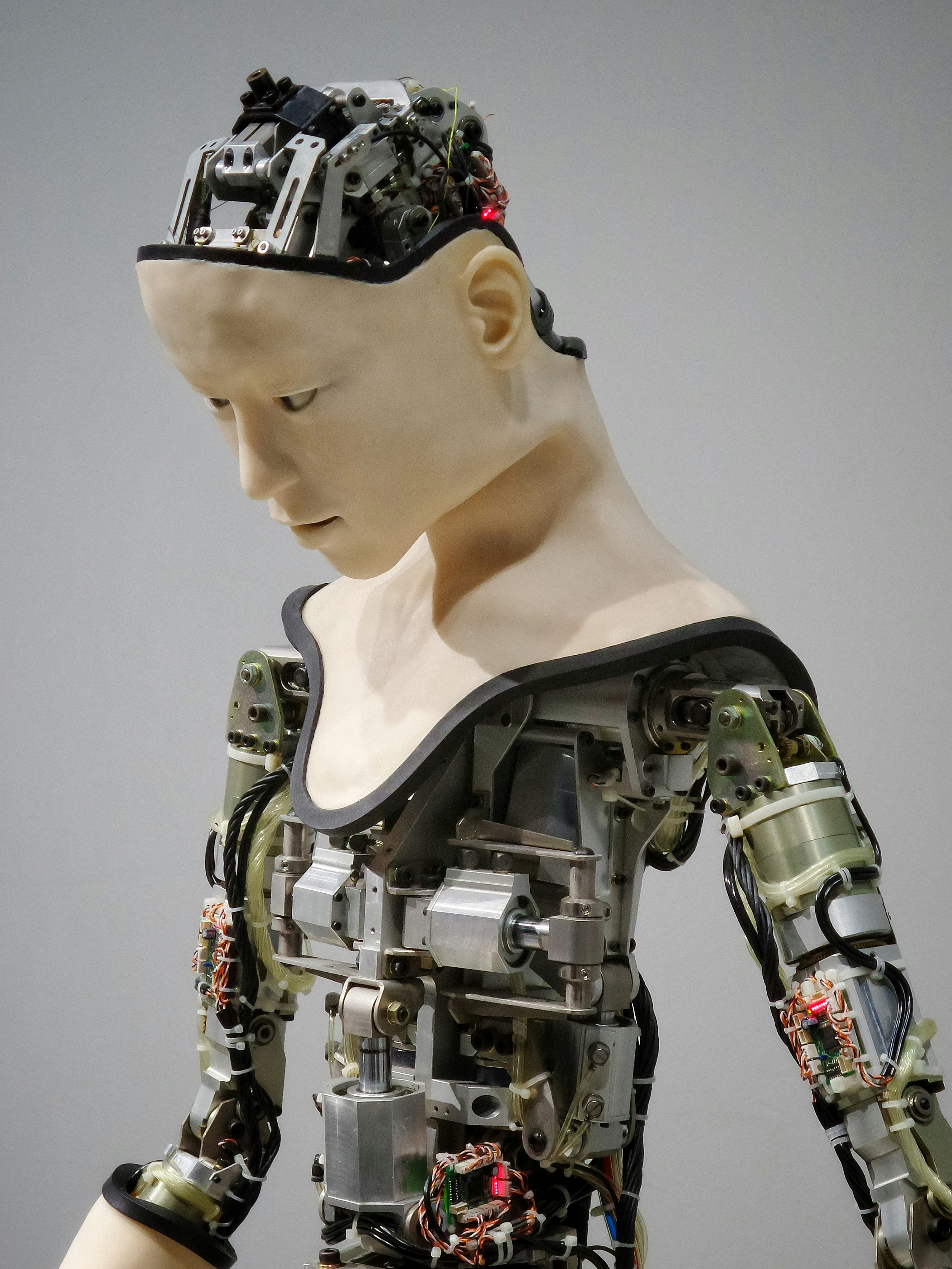

Supply chain management plays a critical role in the success of organizations across various industries. With the increasing complexity in the global marketplace, many companies are turning to automated supply chain management solutions to address emerging challenges. In this article, we will explore the benefits that automation brings to supply chain management processes, ranging from cost savings and increased efficiency to improved decision-making and agility.

Read more...Best Practices for Optimizing Your Supply Chain

- Monday, 17 April 2023

- Supply

- Written by Scott Koegler

As the business environment continues becoming increasingly competitive, optimizing the supply chain is proving to be critical to the success of any organization. With an efficient supply chain, you can reap big in terms of reduced costs, improved customer service, and increased profits. This article will assess the best practices for optimizing your supply chain.

Read more...Most Read

-

-

Feb 13 2013

-

Written by Scott Koegler

-

-

-

Feb 17 2012

-

Written by Scott Koegler

-

-

-

Feb 13 2019

-

Written by Scott Koegler

-

-

-

Jul 18 2017

-

Written by Super User

-